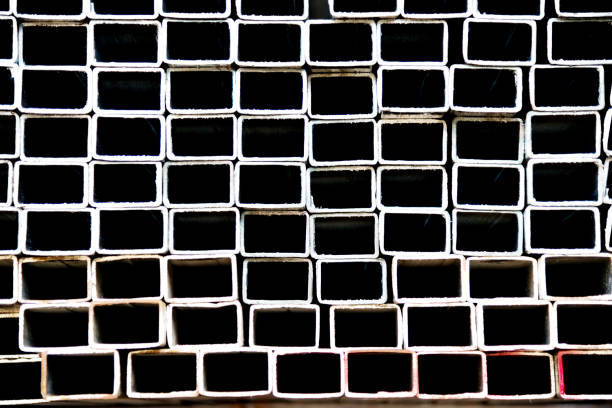

I didn’t think I’d ever say this, but steel shapes have personalities. Some are flashy, some are bulky, and some just quietly do the job while everyone scrolls Instagram reels about stock tips. That’s kind of where Ms square steel sits for me. It’s not dramatic. It doesn’t scream innovation. But it’s everywhere, and once you notice it, you can’t unsee it. First time I really paid attention was at a small construction site near my house. Nothing fancy. Just a half-built gate, some welding sparks, and these neat square bars stacked like Lego pieces for adults.

Steel in general feels boring until you realize how much of modern life would just collapse without it. Literally. Mild steel, especially square sections, are like the reliable friend who never posts but always shows up. Engineers love it, fabricators trust it, and somehow it still doesn’t get the hype that fancy alloys do.

Why square steel quietly wins most real-world jobs

There’s something very practical about a square section. Equal sides, balanced load, no drama. From a financial point of view, it’s like buying a basic index fund instead of chasing meme stocks. You may not brag about it, but it performs. Square steel distributes stress evenly, which makes it easier to design with. Less calculation headache, fewer “oops” moments on site. I’ve heard fabricators joke that square sections forgive small measurement sins. Not officially, of course, but you know what they mean.

A lesser-known thing I stumbled across while doom-scrolling late one night is that square sections often reduce material waste compared to custom shapes. That matters more than people think. Less cutting, less scrap, slightly lower costs over time. In an industry where margins can be thinner than a badly rolled sheet, that’s huge. No one tweets about it, but it keeps projects alive.

The money side of steel that no one explains properly

Steel pricing is weird. One day it’s stable, next day your supplier sends a WhatsApp message that looks like a breakup text. Square mild steel tends to be a bit more predictable though. Because demand is steady across construction, furniture, and even small manufacturing units, prices don’t swing as wildly as niche profiles. It’s not immune, obviously. Global iron ore prices, freight costs, government policies, all that stuff still mess with it.

A small stat I found interesting, and I’m paraphrasing from memory so don’t quote me in a board meeting, is that square and rectangular sections together make up a surprisingly large chunk of structural steel usage in low-rise construction. People assume I-beams dominate everything, but for everyday stuff like sheds, railings, frames, and supports, square sections quietly dominate.

From gates to gym equipment, it’s oddly everywhere

Once you start noticing square steel, you’ll see it everywhere. Staircase railings, bed frames, those minimalist tables influencers love posing coffee cups on. Even gym equipment uses square sections because they’re easy to weld and look clean. There’s an aesthetic angle too. Squares feel modern. Circles feel industrial. That’s probably why interior designers sneak square steel into “rustic modern” homes and pretend it’s a bold design choice.

I once helped a friend source steel for a tiny café renovation. Budget was tight, expectations were not. Square mild steel saved the day. Strong enough, affordable, and easy to paint black for that industrial vibe everyone suddenly wants. Nobody asked what grade it was. They just cared that it didn’t wobble.

Online chatter and the unglamorous truth

If you hang around construction forums or even certain Reddit threads, you’ll see people arguing about steel like it’s a sports team. Hot rolled versus cold rolled. Imported versus local. But square mild steel usually gets a nod of quiet approval. No fanfare. Just “yeah, that’ll work.”

On social media, the only time steel trends is when prices spike and contractors panic-post stories. Square sections get mentioned in passing, usually followed by a crying emoji and a calculator screenshot. That tells you something. It’s essential enough that people worry when it changes.

Mistakes, myths, and stuff I got wrong at first

I used to think all square steel was basically the same. Turns out, not really. Thickness, tolerance, finish, all matter. I once assumed a cheaper option would behave the same under load. Bad assumption. Not catastrophic, but enough sag to make me double-check specs next time. That’s the thing with steel. It looks solid, but details matter.

There’s also a myth that square sections are weaker than round ones. Not exactly true. It depends on application. Squares resist bending differently, and in many structural uses, they’re actually easier to reinforce. Engineers know this. Internet experts sometimes don’t.

Where this leaves us, realistically

Steel isn’t going anywhere. Concrete cracks, wood rots, trends change. Square mild steel just keeps doing its job. It’s not exciting, but neither is your phone charger until it stops working. In the long run, reliability beats hype. That’s probably why so many builders default to it without thinking twice.

By the time you reach the end of a project, no one thanks the steel. They thank the design, the paint, the lighting. But underneath all that, holding things straight and steady, is usually something very simple. Very square. And yes, very often Ms square steel doing what it’s always done, without asking for credit.